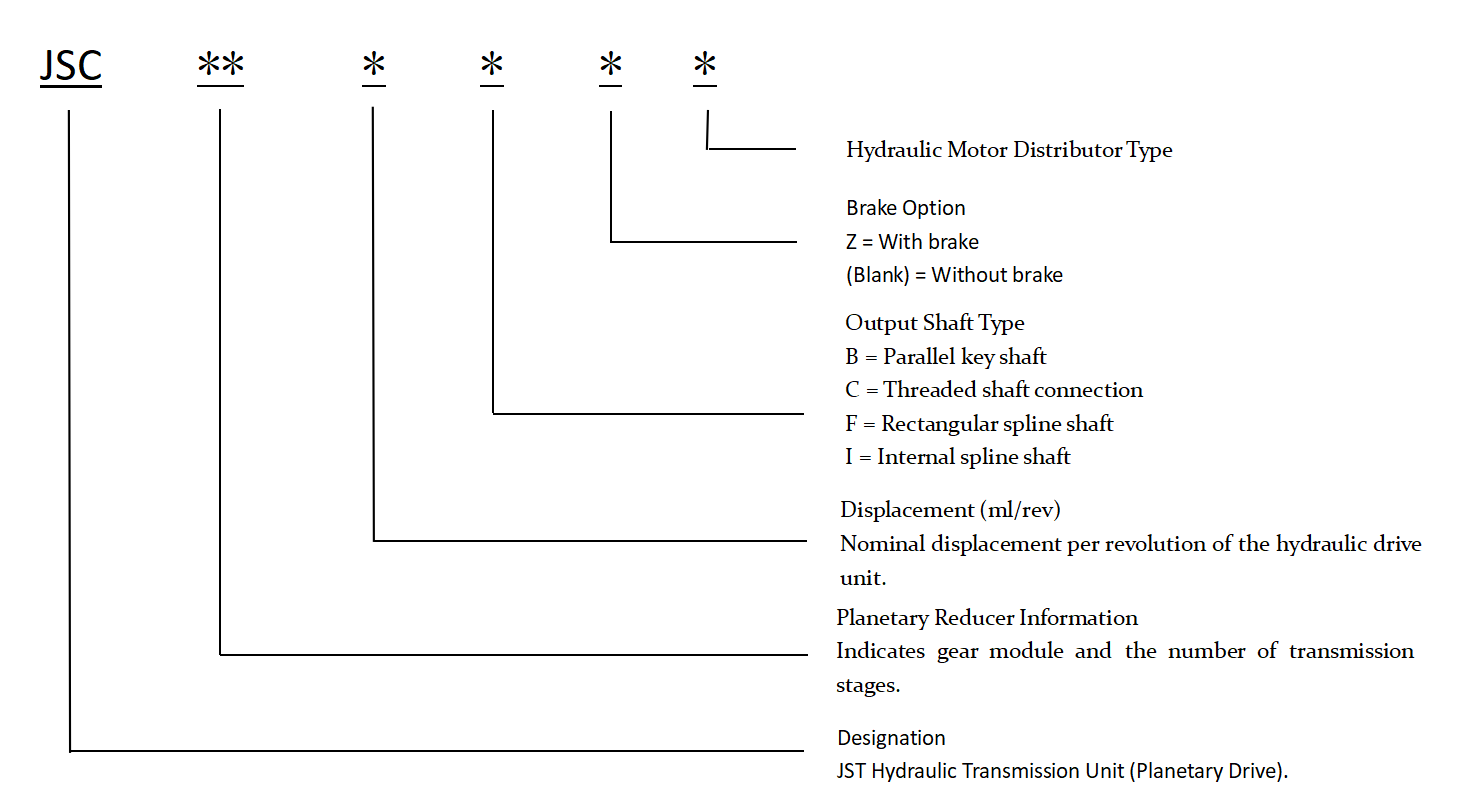

JSC Series — Hydraulic Transmission Units

• Integrated drivetrain: motor + planetary reducer + brake + distributor in one robust, space-saving unit.

• High reduction flexibility: ratios from 1:4 to 1:500 (single to multi-stage), balancing speed and torque density.

• High load bearings: tapered-roller packs absorb travel/turning loads without premature wear.

• Efficient & smooth: optimized tooth geometry and precision machining for >95% single-stage efficiency and stable low-speed motion.

• Non-standard customization: displacement, shaft/mounting interface, brake type, and valve logic can be tailored to your machine.

• Export-ready interchangeability: mounting patterns and performance compatible with leading imported drives.

• Rated Output Torque: ~0.5–200+ kNm (model-dependent).

• Working Pressure: 16–25 MPa (H-option at 20 MPa).

• Displacement Range: wide coverage (typical ~80–1000 ml/rev; configurable per duty).

• Reduction Ratios / Stages: 1:4–1:500, single / two / three-stage planetary.

• Speed Range: from creeping speeds to application-defined top speeds (per flow & ratio).

• Output Interfaces: parallel key, splined, internal spline; customizable flanges and mounting faces.

• Brake & Control: integrated multi-disc brake; optional balance / relief / anti-cavitation / flushing valves in the distributor.

• Durability Options: hardened & ground gears, corrosion-resistant finishes, enhanced sealing, sensor ports (speed/temperature).

• Track & Wheel Drives: excavators, crawler carriers, engineering vehicles.

• Drilling & Foundation: rotary drilling rigs, DTH/rock drills, piling rigs, tunneling equipment.

• Mining & Road Machinery: compact high-torque final drives for continuous duty.

• Industrial Drives: heavy conveyors, mixers, rotary mechanisms requiring compact, high-torque transmission.