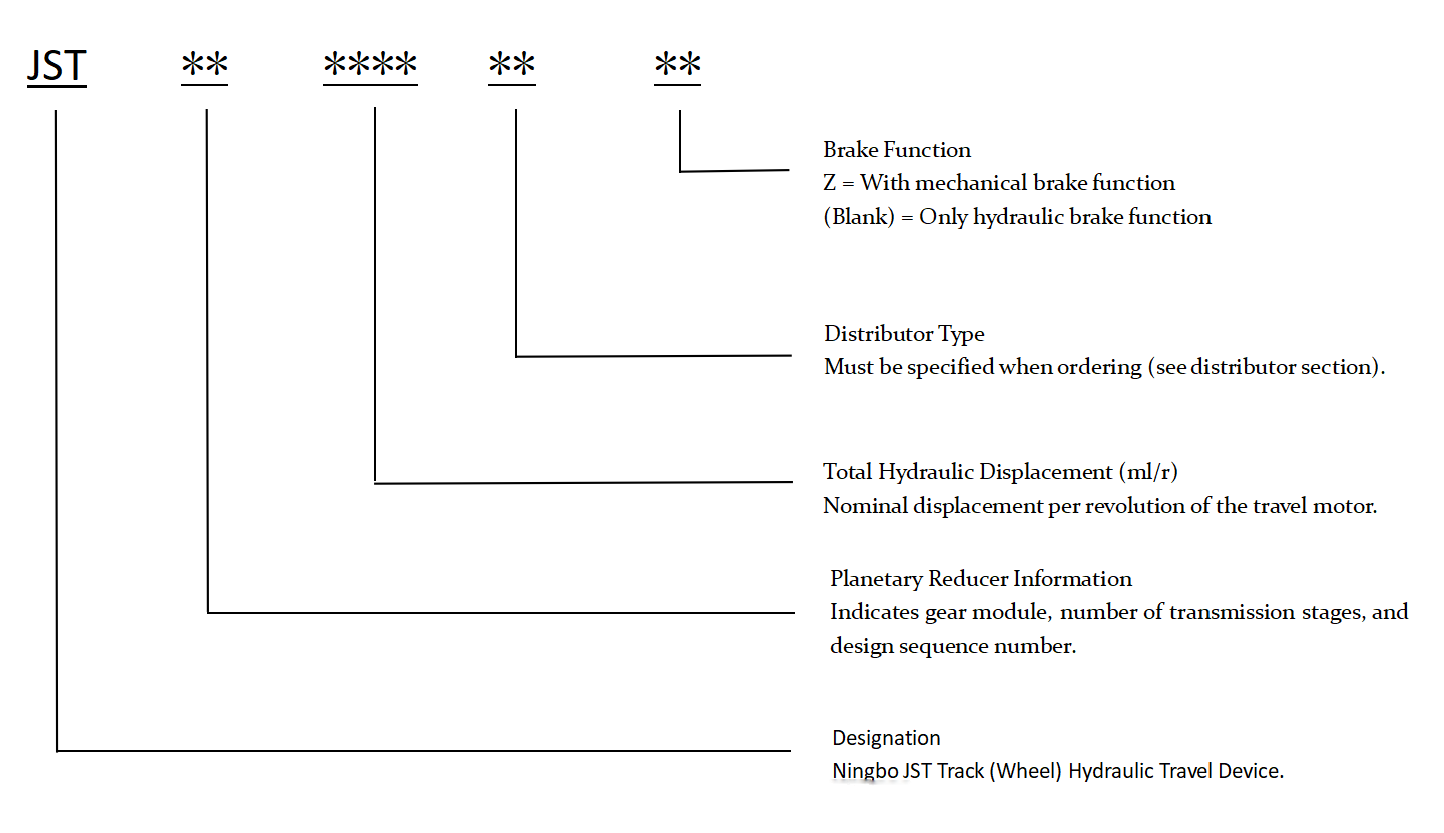

JST Series — Hydraulic Travel Motor Final Drive Units

• Shell-drive direct connection: motor body drives sprocket or track wheel directly, reducing connection parts and increasing reliability.

• High radial and axial load capacity: uses heavy duty tapered roller bearings / cone-roller bearing sets, built to resist track torque, turning loads, and side-thrust.

• Planetary gear reducer(s): single- or two-stage planetary reduction for high torque multiplication, allowing machines to push and climb under load with low motor displacement.

• Integrated braking and control: built-in brake and valve block allows safe parking, smooth stopping, and resistance to rollback.

• Efficiency under harsh duty: optimized lubrication paths, quality sealing, and precise machining reduce losses; high overall efficiency even under load.

• Interchangeable with imported units: dimensions, mounting bolt patterns, sprocket diameters compatible with standard tracked machines.

• Torque output: continuous and peak torque optimized for medium to large tracked machines.

• Reduction ratio: single-stage or two-stage planetary reducers, customizable gear ratios per machine duty.

• Working pressure: rated for high hydraulic pressures (e.g. ~300-400 bar), depending on model.

• Speed range: low travel speeds under heavy loads; top travel speeds dependent on sprocket pitch and hydraulic flow.

• Shaft / mount types: multiple spline / keyed / flange / shell drive options; built-in sprocket or interface for sprocket wheel.

• Sealing & bearings: marine / offroad quality seals, tapered roller / cone bearings for combined radial + axial loads; optional external bearings.

• Dimension options: multiple size mounts, sprocket diameters, bolt patterns to fit tracked machines & crawler wheels.

• Excavators & Drills: crawler excavators, non-excavation drills, rock drills, rotary drills, down-the-hole drills.

• Tunnel Boring & Tunneling Machinery: full track travel / wheel driven systems.

• Track & Mobile Vehicles: crawler carriers, engineering vehicles, tracked crawler road machinery.

• Mining & Geotechnical Equipment: machines that operate in mining / rock / soil conditions with high side loads.

• Construction Machines: track drives / wheel drives for undercarriage of dozers, shield machines, tracked cranes.