BM Series — Orbital Hydraulic Motors

• True orbital design with only a few moving components, reducing friction and improving reliability.

• High volumetric efficiency with minimal internal leakage, ensuring stable torque under heavy loads.

• Smooth low-speed control, stall-resistant even below 10 rpm.

• Three-zone pressure design (inlet, return, case) protects seals and bearings, extending service life.

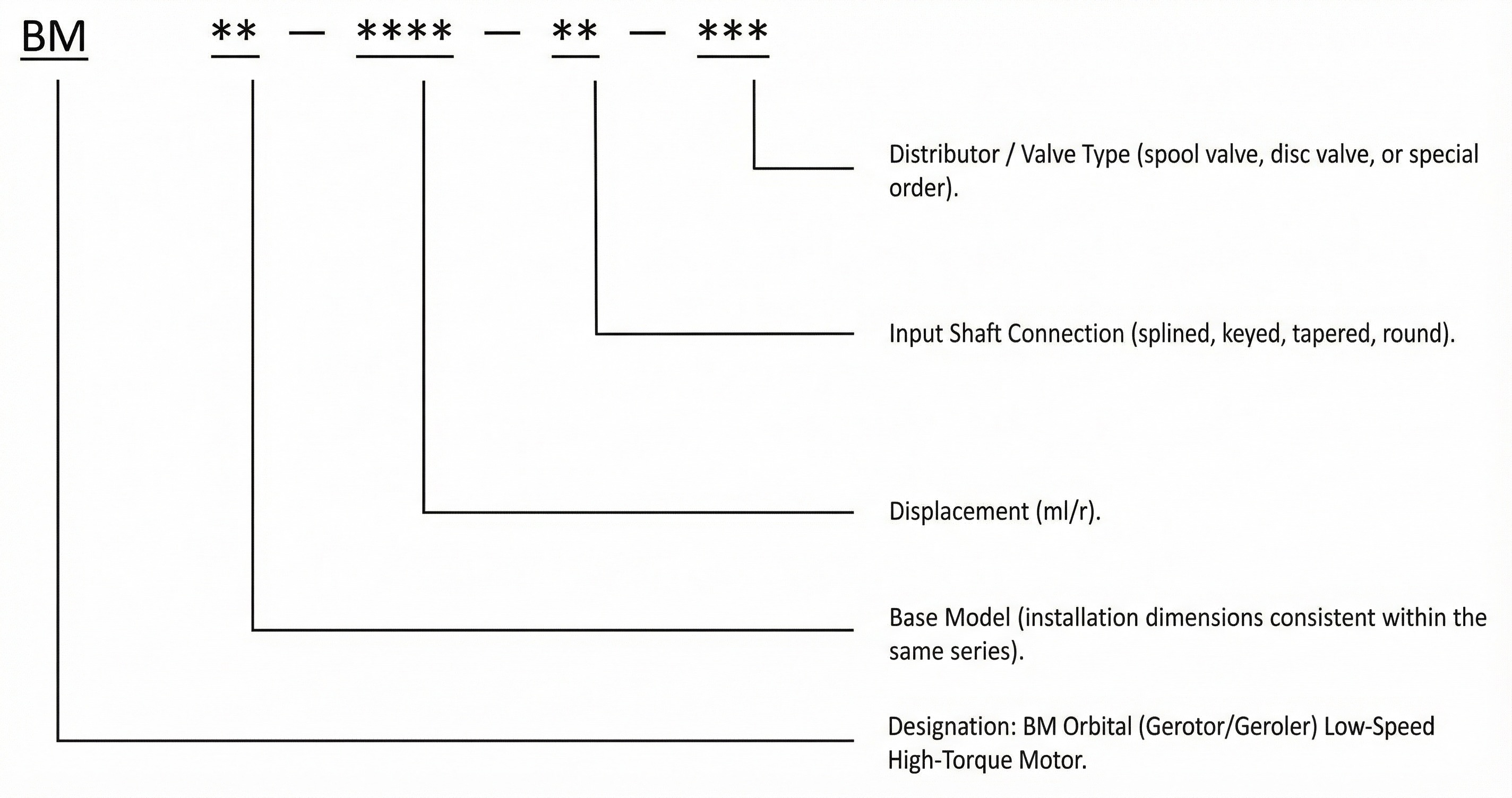

• Wide configuration flexibility: multiple shaft options (splined, keyed, straight), mounting styles (flange, wheel, standard).

• Optional features: case drain, dual-speed modules, integrated brakes, corrosion-resistant coatings.

• Proven durability in harsh operating environments, across temperature and fluid viscosity ranges.

• Displacement Range: approx. 30 – 1000 ml/rev (varies by configuration).

• Torque Output: low-to-medium torque LSHT envelope; continuous torque up to thousands of Nm depending on displacement and pressure.

• Working Pressure: continuous up to 310–350 bar; intermittent peaks higher.

• Speed Range: stable operation from creeping speeds below 10 rpm up to several hundred rpm.

• Power Output: scalable to match light- and medium-duty machinery.

• Options: SAE or BSP porting, multiple shaft and flange types, protective coatings, case drain options.

• Fluid Compatibility: suitable for standard anti-wear hydraulic fluids; viscosity and temperature ranges conform to international standards.

• Agriculture: tractors, sprayers, mower decks, augers.

• Construction & Utility: skid steer attachments, sweepers, conveyors, compact loaders.

• Forestry & Land Clearing: mulchers, brush cutters, wood processing equipment.

• Material Handling: conveyors, small winches, lifting systems.

• Off-Road & Mobile Equipment: steering drives, swing drives, light-duty propel systems.